The helium recovery process was analyzed in a plant that manufactures components for residential and commercial HVAC systems. We compared the costs, savings, and performance between their current traditional helium recovery unit and the PURE recovery system.

The company operates 22 hours a day, 350 days a year, and has an annual production of 750,000 pieces, or an average of 100 pieces per hour.

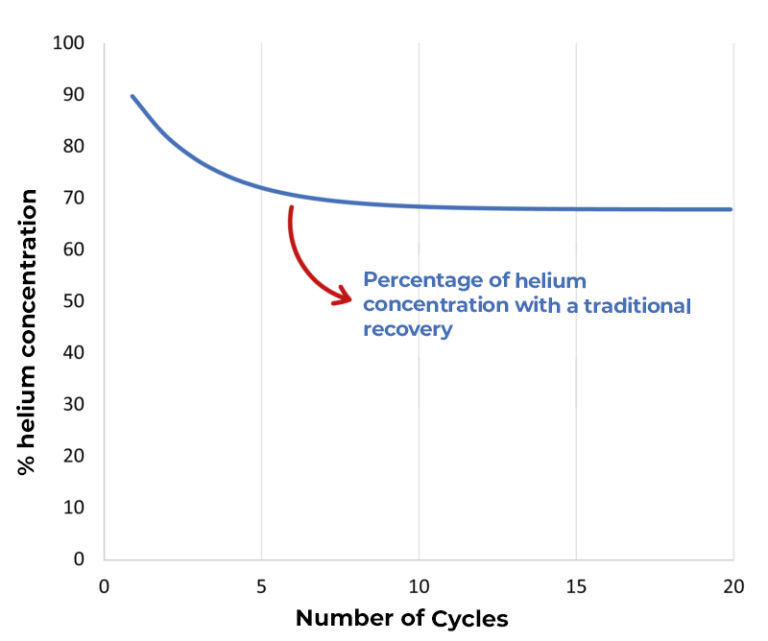

During the leak test process, after just 20 cycles, the helium concentration in the traditional recovery unit degrades – from 89% at the end of cycle 1 to 66% by the end of cycle 20.

The key issue, as illustrated in the graph above, is the dilution of helium concentration during the leak test cycles. Due to the nature of traditional helium recovery units, they cannot avoid gas dilution.

This leads to high helium consumption, necessitating the addition of PURE helium to compensate for the dilution that occurs cycle after cycle. This high helium consumption results in a significant cost for helium cylinders.

Currently, with the traditional helium recovery unit, about three helium cylinders are consumed each day. Considering that one helium cylinder costs 500 USD, the company incurs a daily cost of $1,500 USD just on helium. Annually, this represents an expenditure of $525,000 USD.

Our new revolutionary helium recovery system, PURE®, is capable of maintaining the helium concentration during leak test cycles without the need to add pure helium to improve the concentration.

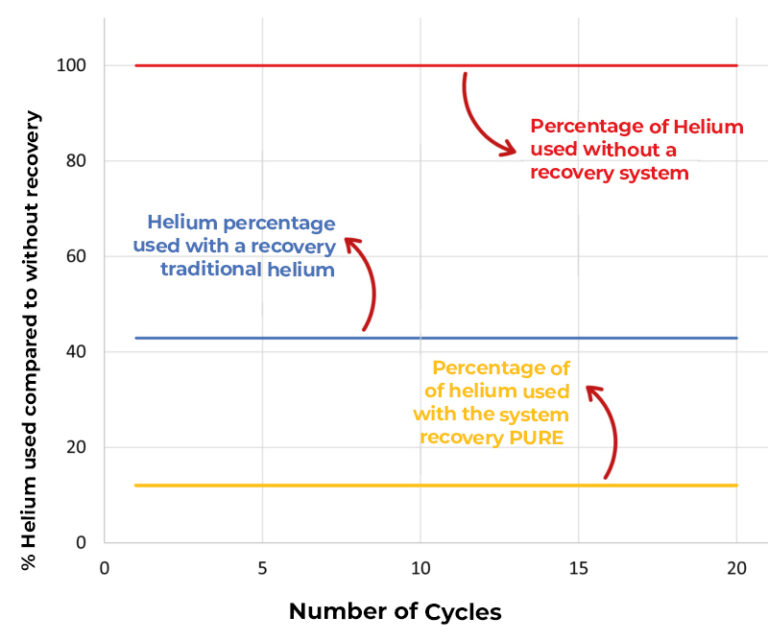

The helium concentration after 20 leak test cycles with the PURE recovery system is illustrated below.

Thanks to VES Global’s developed technology, air, and helium particles are mechanically separated within the PURE recovery system, improving helium concentration and providing consistent, repeatable savings.

The data is as follows:

The traditional helium recovery unit achieves a 57% reduction in helium consumption.

Meanwhile, the PURE recovery system achieved over an 86% reduction (almost 30% more savings with each test cycle) compared to the traditional recovery system.

The traditional helium recovery unit currently uses three cylinders of helium a day. In contrast, with the PURE recovery system, consumption will be reduced by more than three times, i.e., to less than one cylinder per day.

Currently, the plant consumes three helium cylinders daily. The average cost per helium cylinder is $500 USD; multiplying this by the three required cylinders gives a daily total of $1,500 USD.

Remembering this residential and commercial HVAC company has 350 production days annually, multiplying the daily $1,500 USD by the 350 production days results in an annual cost of $525,000 USD, or the consumption of 1,050 helium cylinders per year.

Considering the helium savings that the PURE system offers, we go from consuming 1,050 to 342 annual helium cylinders with PURE. This means that instead of spending $525,000 USD, we will only spend $171,000 USD.

With the PURE recovery system, this residential and commercial HVAC company is saving just over $353,000 USD annually in helium consumption.

When comparing a traditional helium recovery unit versus the PURE recovery system, it becomes clear that PURE is a far more effective choice. It not only reduces helium consumption and simultaneously improves concentration but also increases recovery percentage and performance.

In conclusion, the long-term financial savings using the PURE recovery system will be in the triple digits, with a ROI IN LESS THAN 2 YEARS.

Start saving on helium by requesting a personalized consultation with our leak detection experts.

St Modwen Road, Trafford Park

Manchester, M32 0ZE, UK

T +44 161 866 8860

3901 Bestech

Dr. Suite/Unit 300

Ypsilanti, MI 48197, USA

T +1 734 340 6085

E salesUSA@vac-eng.com

Carretera Estatal 431 KM1.3

Bodega 26S, PKCo El Marqués

Queretaro 76246, Mexico

T +52 442 402 1122

Vacuum Engineering Services USA. All rights reserved.