Accuro is an innovative, bespoke helium leak detection machine that employs mass spectrometry without the need for a vacuum chamber. Fully customisable to your exact industry requirements, it reliably finds leaks down to 1.0 × 10⁻³ mbar·L/s using either helium or hydrogen even on products that have undergone thermal processing.

There is a significant performance gap between vacuum chamber leak testers and other differential pressure-based solutions. Conventional systems often generate false rejections due to calibration cycle errors, leading to high scrap levels.

Moreover, the investment for a vacuum chamber-based leak detection system is up to 6 times higher than for differential pressure solutions and 4 times higher than for localized leak detection systems.

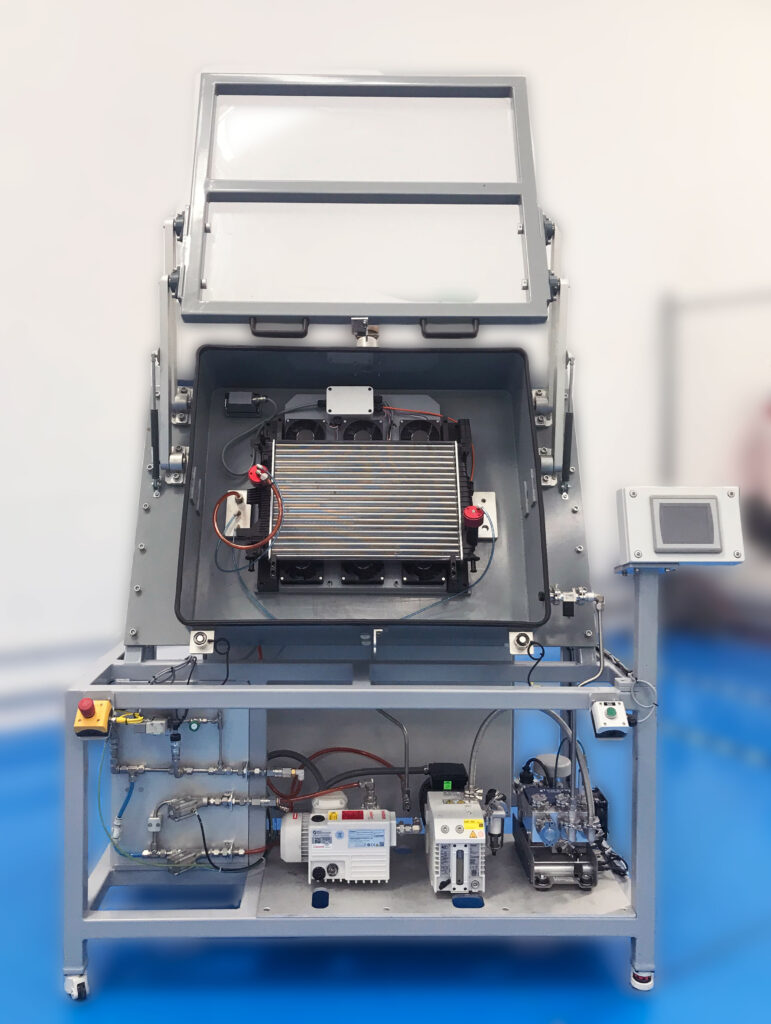

The product is placed into a tool fixture within the test chamber; the operator initiates the cycle, with manual or automatic door operation

A preliminary leak test using air/vacuum is performed to verify that the product does not have an excessively large leak.

The product is then pressurised with pure helium inside the test chamber.

In the event of a leak, helium escapes and mixes uniformly with atmospheric air through built-in turbines.

A mass spectrometer, directly connected to the chamber, accurately quantifies the leak rate.

The system continuously monitors the leak rate. If it exceeds the limit, the test stops and the product is flagged for rejection; if below the limit, the test ends and the product is approved.

Accuro can consistently detect leaks as low as 1.0e-03 mbarL/s using helium or hydrogen, ensuring quality even for thermally treated products.

The system can be automated to meet your specific requirements and budget—manual, semi-automatic, or fully automatic.

Accuro offers a Cpk of 1.45, exceeding the industry minimum standard of 1.33, even for products affected by thermal processes or volume expansion during testing.

With easily interchangeable tooling, the test chamber can be quickly adapted for different products and sizes.

Emergency stops (hardwired E-stops) are available on both the front and rear sides, with secure HMI parameters and pressure relief valves on all service lines.

Equipped with either AB or Siemens PLCs, a 6” touchscreen HMI, integrated traceability system, and Industry 4.0 add-ons, Accuro offers scalable I/O for modern production environments.

An automotive radiator manufacturer producing 60 radiators per hour was initially testing units using a differential pressure system that measured leak rates at 4 sccm at 2.5 barA. However, the system yielded very high rejection levels and inconsistent leak rate values.

To address these issues, the customer implemented several workarounds:

After migrating to the Accuro system the process was radically improved. Radiators were tested directly at the end of the welding process without the need for a cleanroom. Calibration was reduced to once per shift, and a dual-chamber system enabled the production rate to consistently reach 60 pieces per hour.

Whether you’re interested in learning more about our Helium Leak Detection by Mass Spectrometry solutions or already have a specific need in leak detection solutions, send us a message. We promise to get back to you within 24 hours.

St Modwen Road, Trafford Park

Manchester, M32 0ZE, UK

T +44 161 866 8860

3901 Bestech

Dr. Suite/Unit 300

Ypsilanti, MI 48197, USA

T +1 734 340 6085

E salesUSA@vac-eng.com

Carretera Estatal 431 KM1.3

Bodega 26S, PKCo El Marqués

Queretaro 76246, Mexico

T +52 442 402 1122

Vacuum Engineering Services USA. All rights reserved.